CHIAN CHANG

Precision Power Presses

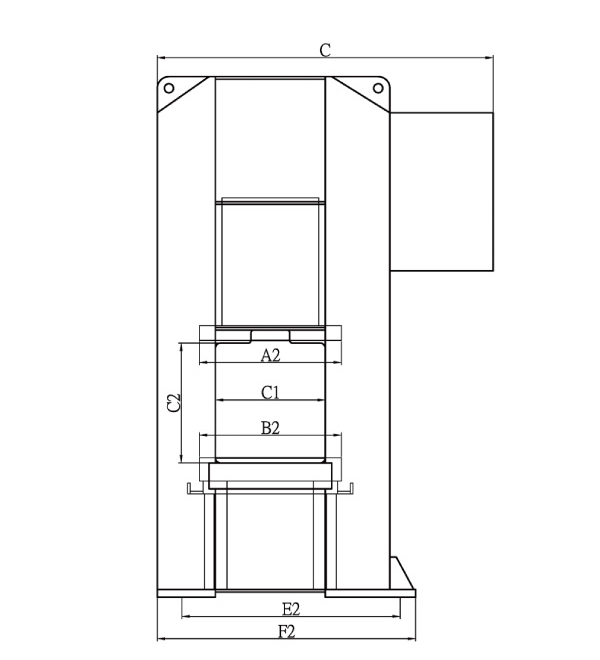

H-Frame Double Crank Link Motion Precision Power Presses

HL2P Series

200 ~ 600 tons

High rigidity frame, link motion and processing characteristics, advanced multifunctional controller, wet type clutch brake, and eight-face wide-and-long guide rail.

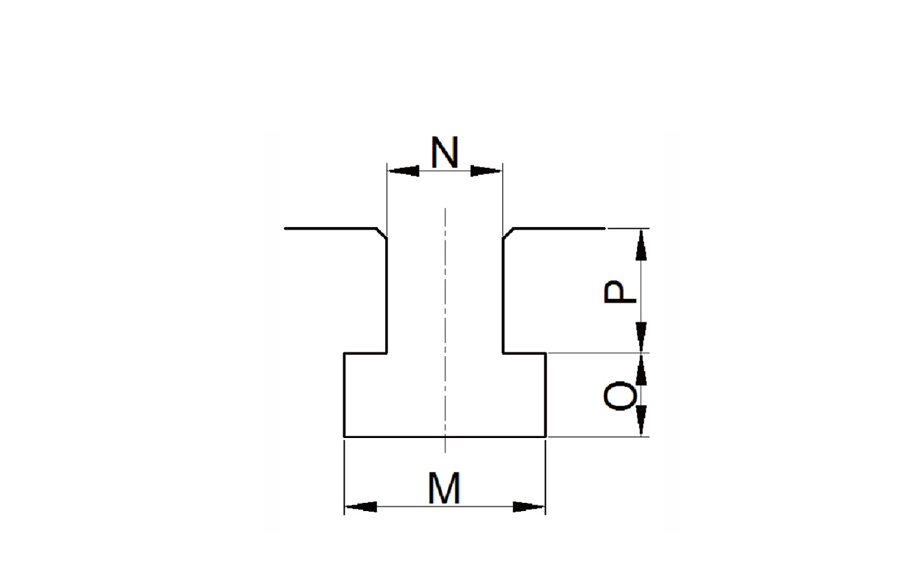

- Eight-face wide-and-long Guide Rail Detail

- High Rigidity Frame Detail

- Advanced Multifunctional Controller Detail

- Link motion and processing characteristics Detail

- Wet Type Clutch Brake Detail

- Stamping Time Curve Comparison Chart Detail

- Touch Screen Control Panel Detail

- Single/Two-hand Push Button Operation Stand Detail