CHIAN CHANG

Precision Power Presses

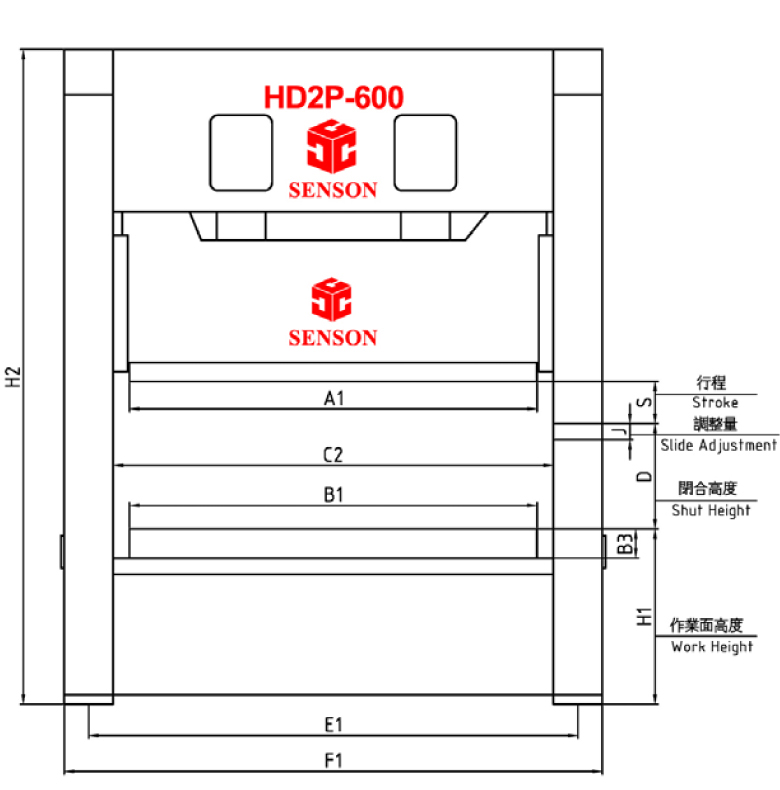

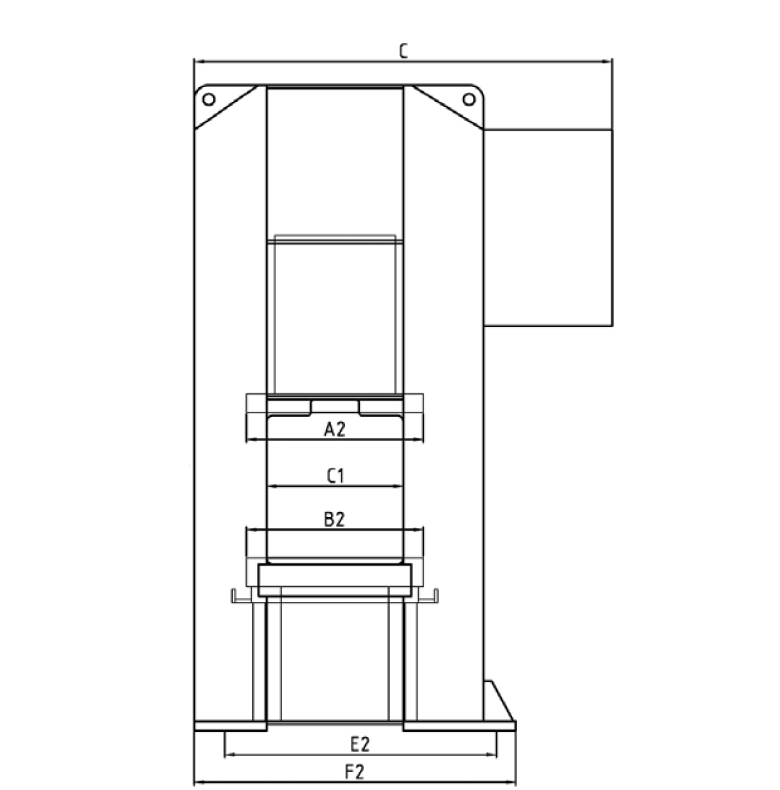

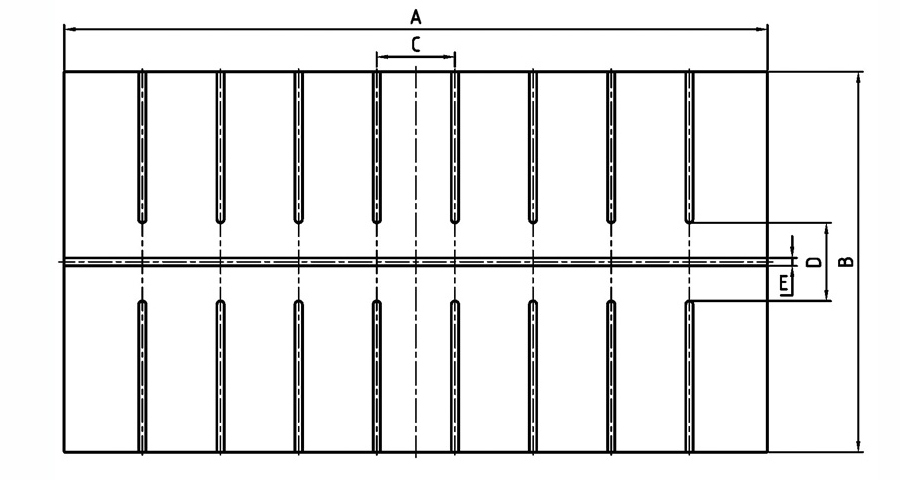

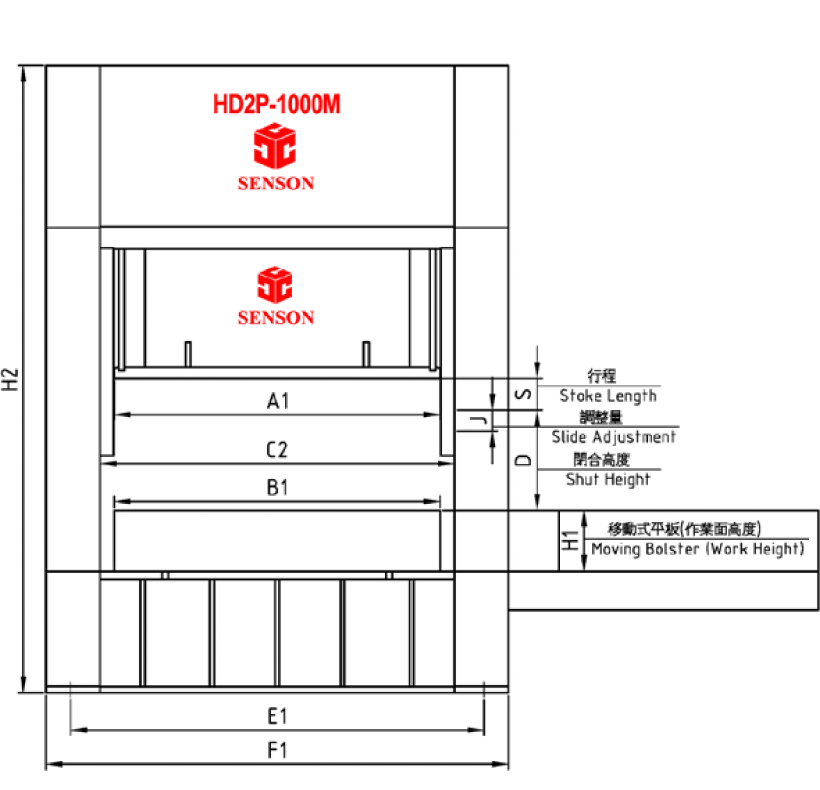

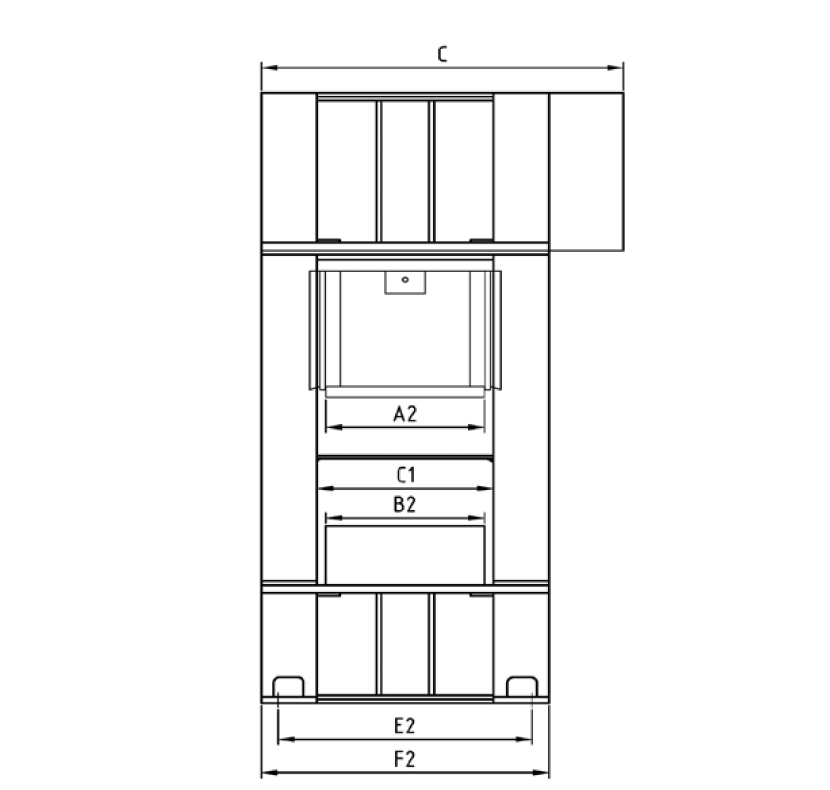

H-Frame Double Crank Precision Power Press

HD2P Series

200 ~ 1600 tons

Micro computer and encoder synchronous controls give a true readout of pressing operations at all times. Used for single punch, progressive die, or drawing operations.