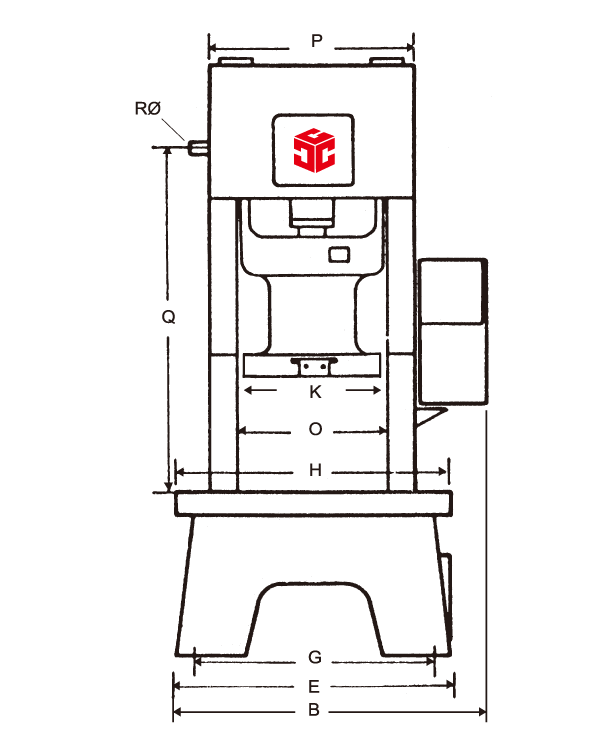

CHIAN CHANG

Precision Power Presses

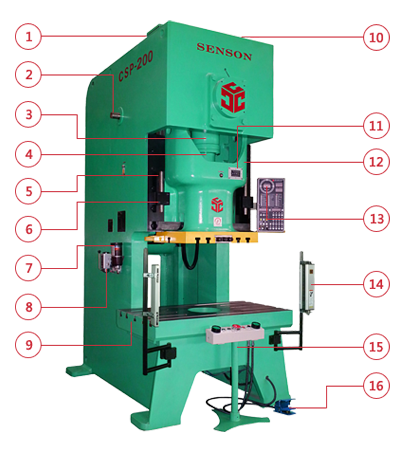

C-Frame Single Crank Precision Power Press

CSP Series

25 ~260 tons

Broad slide bottom and bolster are suitable for drawing and punching operation with various automotive, motorcycle and machine components, appliance and hardware parts, and computer parts like Cases, CD-ROM, Fans, and PC boards.

- Counter balancer (Equilibrating cylinders)

- Power take-off feed shaft (feed direction: left→right)

- Connecting rod

- Ball Rod

- Six-face wide-and-long guide rail

- Knock out device

- Manual grease pump

- Oil pump

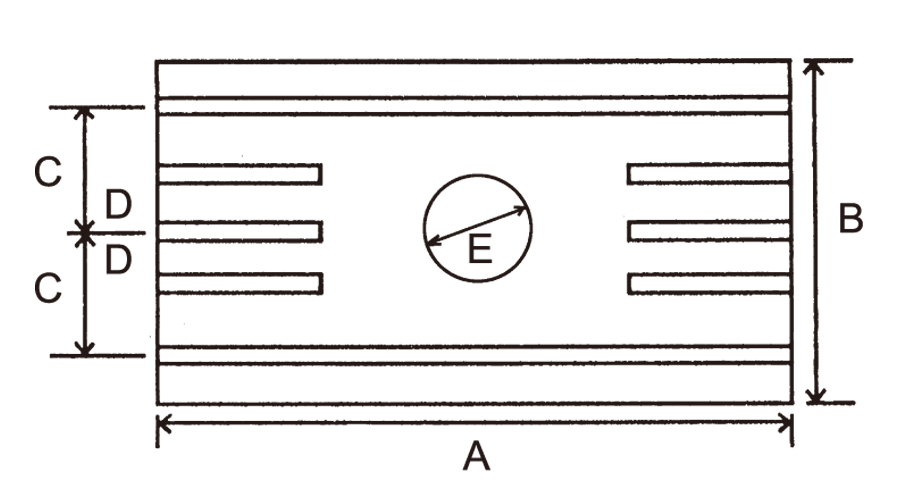

- Bolster

- Anti-repeat device (Overrun detector)

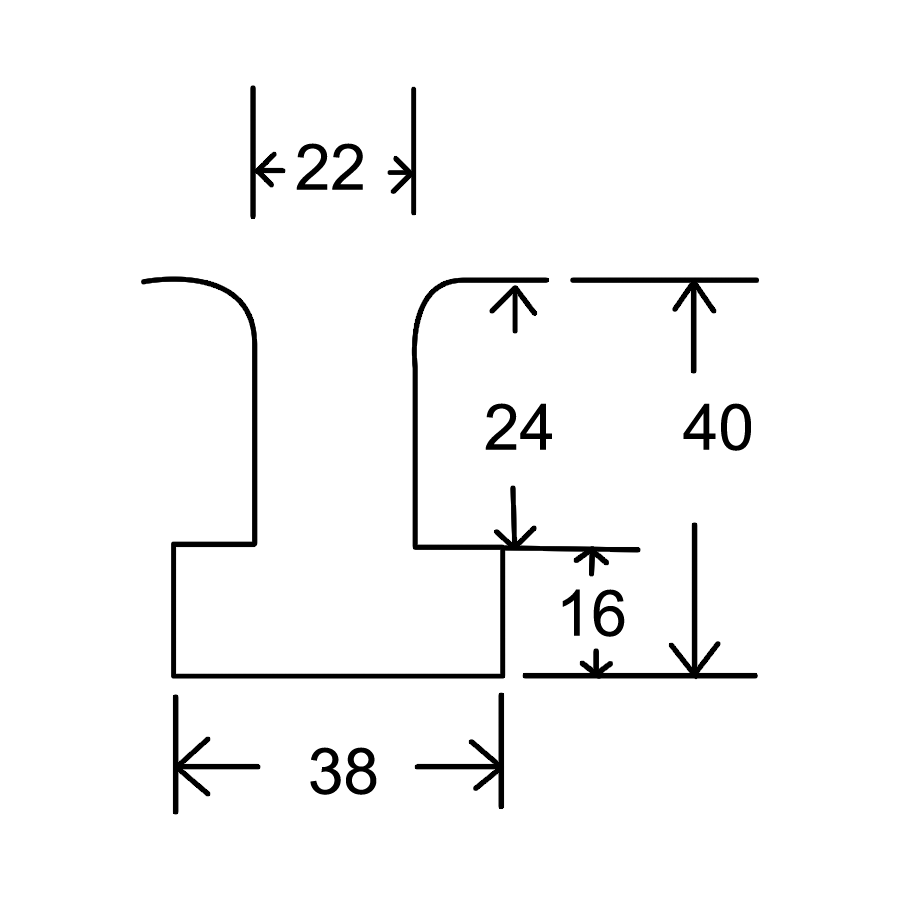

- Die Height Indicator Detail

- Slide

- Crank angle LED display

- Safety light curtain

- Portable push button operation stand

- Foot switch

- Encoder

- Touch screen control panel and box

- Air pressure regulator

- Main motor [Variable speed(V.S) motor for overseas market]

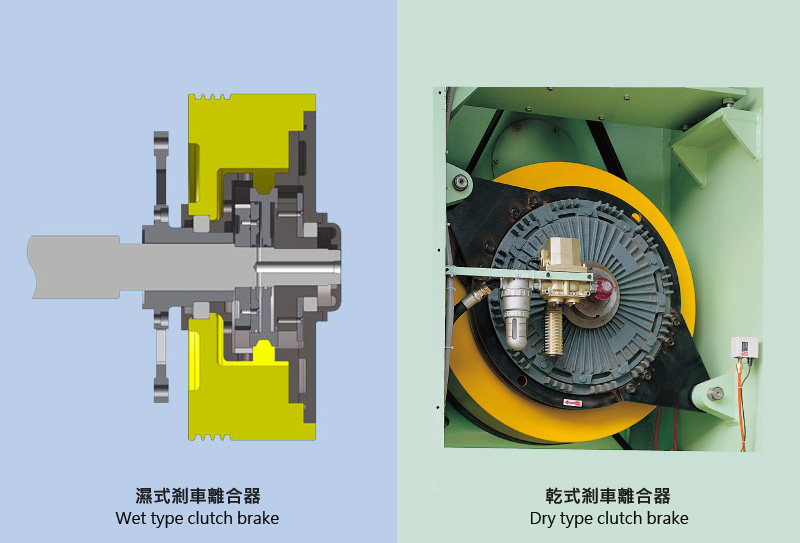

- Wet Type Clutch Brake Detail

- Slide adjust motor

- Hydraulic overload protector

- High rigid frame